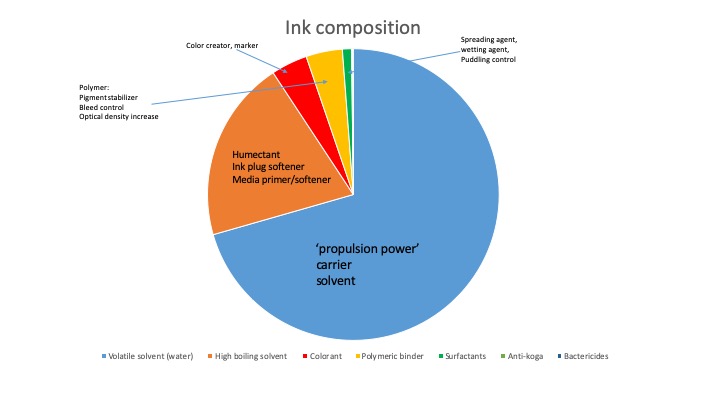

In order to be delivered on the substrate, the colorants need to be either dissolved or dispersed in a solvent. The most popular in solvent is water, as it is cheap, abundant and safe; many colorants can be dissolved or dispersed in water. Dissolved colorants are known as dyes, whereas the dispersed ones are known as pigments. In terms of the chemical structure, dyes and pigments often share a similar chromophore chemistry and differ only in solubilizing groups: dyes have grafted sulfo- or carboxy groups, whereas pigments have none.

Water is a moderately volatile solvent and it gradually evaporates after the ink is printed. After drying, the colorant becomes weakly or strongly bound to the media. The ink design can be done to enable either; however, in most cases, a strongly bound state is preferred as then the prints can withstand handling and environmental factors such as water spray or a dry rub.

The colorant and a carrier solvent are the two essential components. However, If one wants the ink to print reliably from an inkjet printhead, and spread well on the printing substrate, many other components are required in the inks. Thus, a high boiling organic solvent is often present in addition to water. After water evaporates, the solvent stays behind, or evaporates only very slowly. This solvent may serve many purposes, the most common one being softening of the ink plug that forms at the inkjet nozzle, as the water evaporates from the inks. If there would not have been for this solvent, the pigment particles would have clumped together and would needed to be cleaned from the nozzle each time the printhead have started to work.

Polymers are often added to pigment-based inkjet inks. The polymers serve many purposes, from the stabilizing of the pigment particles, to improving durability of the prints. Polymers in inks are definitely a double-edged sword, as they often can cause severe clogging of inkjet nozzles.

Surfactants are often added to inkjet inks to improve their spreading on media and to control their wetting of the inkjet orifice plate and stability of the liquid jet. There are also multiple small additives that are used to bind impurities present in inks as well as to passivate the part of the printhead.