As water from the inks evaporates, a very viscous solid plug forms at the nozzle. This plug will be difficult to remove or to spit out, and the nozzle can become permanently clogged. However, by a careful selection of the organic solvent and the pigment surface modification, it is possible to cause the colorant migration away from the nozzle on storage. As the pigment migrates out, into the standpipe, the printhead becomes more easy to recover after a prolonged storage, as it is filled with essentially pure solvent, with a small fraction of water still present—on the other hand, the pigment is completely gone from the nozzle!

The rate and direction of the pigment particle migration can be the changed by the surface modification of the pigment particles, for example, by the chemistry of its surface groups (1,2).

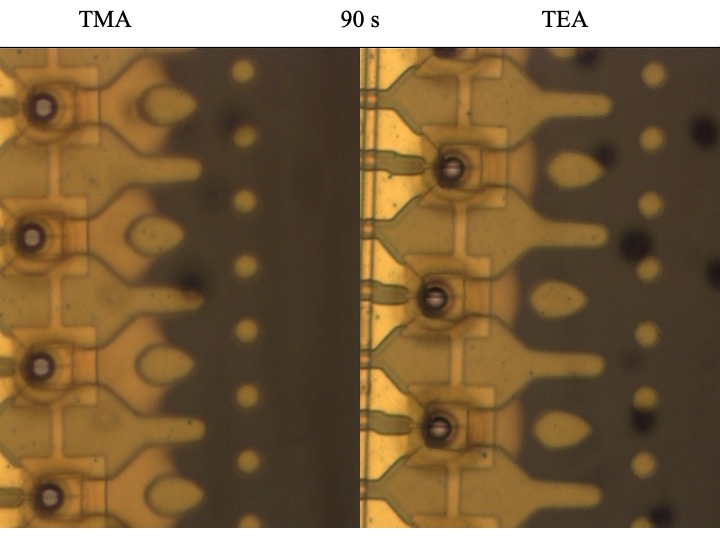

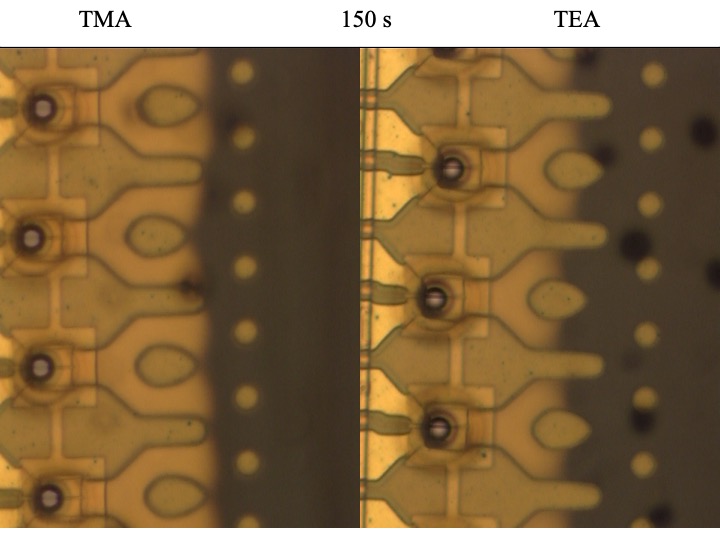

Figure 1 compares the rate of migration of a carbon black pigment modified with sulfo groups with different counter-ions. One can see, that changing the couter-ions from trimethylamine (TMA) to triethylamine (TEA) causes a major reduction in the pigment migration rate (1, 2). The pigment migration is caused by the creation of the solvent concentration gradient as water gradually evaporates, a phenomenon known as diffusiophoresis (3).

Figure 1. Comparison of the pigment retraction rates for carbon black pigments with different couture-ions: TMA (left) and TEA (right).

- Kabalnov, A., Wennerstrom H. Pigments modified with surface couuter-ions. US Patent 20060162612A1.

- Kabalnov, A., Wennerstrom H. Diffusion in Evaporating Solutions. Soft Matter, 2009,5, 4712-4718.

- Anderson, John L.; Prieve, Dennis C. (2006). “Diffusiophoresis: Migration of Colloidal Particles in Gradients of Solute Concentration”. Separation & Purification Reviews. 13 (1): 67–103.